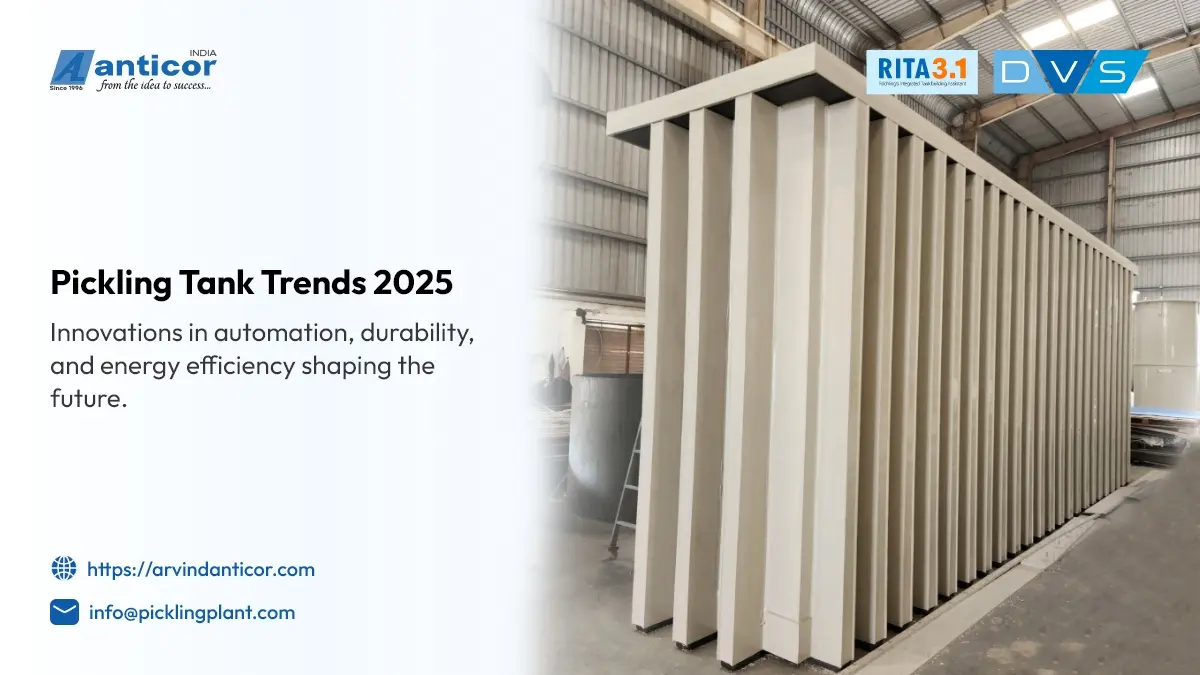

Strategic Partnerships

Integrating World-Class Products, Software, and Technology for Superior Solutions

Polypropylene Pickling Tanks

Polypropylene pickling tanks provides exceptional level of chemical corrosion resistance, is strong, lightweight and durable too. It is compatible with high and low temperatures and has excellent thermal insulating properties too. Polypropylene pickling tanks have many benefits as compared to other traditional metal tanks such as steel, stainless steel and titanium. The benefits include a seamless construction which is responsible for superior resistance to rust, corrosion, chemicals and fuel additives.

We are recognized as one of the top polypropylene pickling tanks manufacturers and PP pickling tank manufacturers in India. Our tanks are engineered for demanding applications across industries including metal finishing, water treatment, and chemical processing. We design and fabricate polypropylene pickling tanks to serve multiple purposes like anodizing, electroplating, acid pickling, fluxing, degreasing, rinsing, and passivation.

Our high quality pp tanks have a sharp structure and possess safety characteristics. The bottom corner of the pickling tanks are with weld-less radius to make it completely leak proof. Our pp pickling tanks in India are manufactured to have high corrosion resistance and are not affected by acids as well.

Our polypropylene pickling tanks are 100% safe and easy to maintain. Such qualities of the products have made us one of the leading polypropylene pickling tanks manufacturers in India. Our technicians use the latest technology in programmable extrusion welding and automated butt welding machines to fabricate polypropylene pickling tanks.

Arvind Anticor has become one of the most preferred polypropylene pickling tanks manufacturer in India as we can create a custom polypropylene pickling tanks solution for your unique needs. The multiple industry application of our products has made us a popular pp pickling tank manufacturer and exporter. The tanks can be used right from chemical storage and metal finishing to pharmaceutical industry – mostly to store liquids.

Specifications

- Planning & construction of tank system with fume exhaust system.

- Robust design of tank made out of Industrial Thermoplastic.

- Environment friendly Fume Extraction System, avoiding corrosion of surrounding steel construction, cranes and roof structure.

- Plastic Tanks available in flat pack modules

- Heating and circulation system available. (optional)

- Tank made from Industrial Thermoplastic and welded with state-of-the-art hot gas extrusion welding process and stress relieved.

- Modules assembled and welded at site for easy transportation.

- 100% leak proof welding.

- Tanks are available up to 40 meter length.

- Polypropylene Pickling Tanks are suitable for mixture of hydrofluoric acid nitric acid and also suitable for HCL acid.

Why Choose Our Tanks?

Exploring Types, Benefits, and Industry Uses

- Pickling Plant & Tanks

- Wire Pickling Tanks & Plants

- Tunnel Pickling Tanks

- Galvanizing Tanks for Structure.

- Galvanizing Tanks for Pipe

- Electroplating Plants & Tanks

- Anodizing Plant & Tanks.

- Hot pickling

- Short pickling time

- Less pickling tanks

- Increased productivity

- Low rejection

- Clean working area

- High employees’ acceptance

- Better pickling quality

- Easy draining of sludge

- Corrosion resistant

- Maintenance free & cost saving

- Reliable welding seam

- Average Tank life upto 20 years

- Integral Fume ducting / Space saving

- Chemical Industry

- Water Treatment Industry

- Steel Industry

- Construction and Infrastructure

- Power and Energy

- Automotive Industry

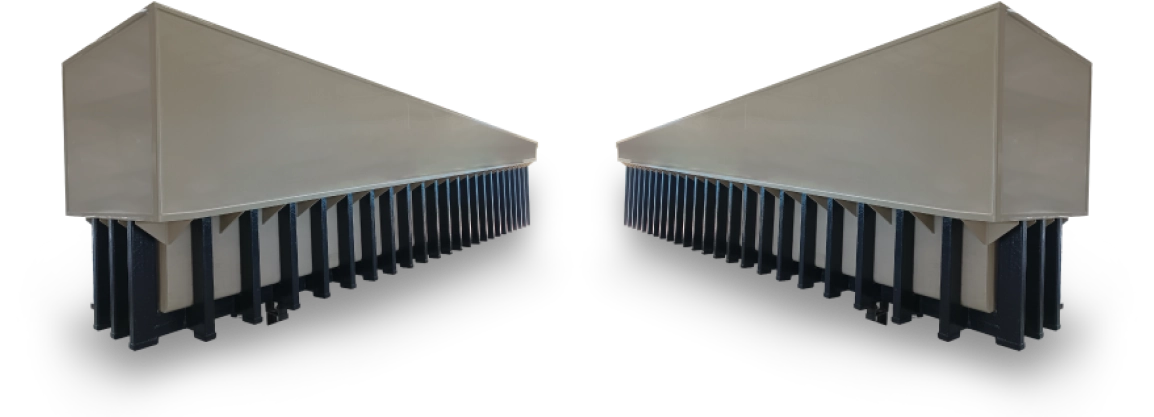

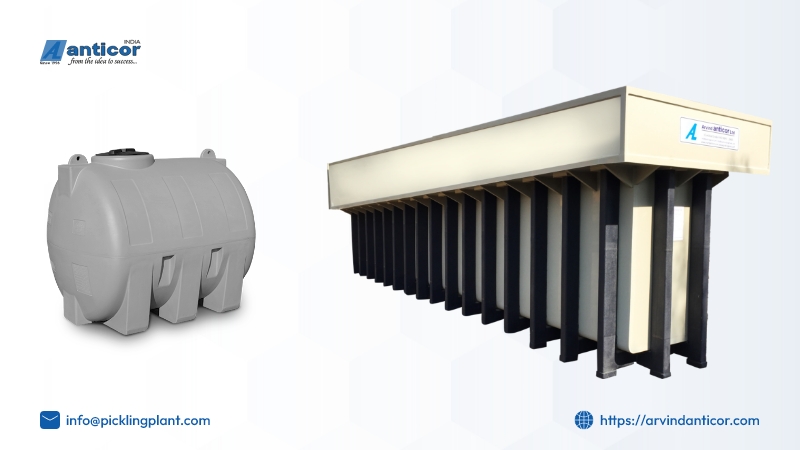

Gallery of Polypropylene Pickling Tanks

A Visual Showcase of Our Durable and Innovative Polypropylene Pickling Tanks.

Any Questions ? We Got You.

A polypropylene (PP) pickling tank is a specialized container designed for the pickling process, typically used to remove impurities, rust, or scale from metal surfaces. Made from polypropylene, it offers excellent chemical resistance, durability, and corrosion protection.

As leading polypropylene pickling tanks manufacturers, we design these tanks to endure highly corrosive chemicals and harsh environments.

Yes, polypropylene has good thermal stability and can typically withstand temperatures up to 85-100°C, depending on the tank’s design and the concentration of the chemical used.

Yes, polypropylene pickling tanks can be customized in terms of:

- Size and capacity

- Thickness of the walls

- Fittings, outlets, and overflow mechanisms

- Additional reinforcements for structural strength

- Integration with heating coils or fume exhaust systems

Polypropylene pickling tanks are highly durable and can last for many years with proper maintenance. They are resistant to chemical corrosion, UV exposure, and mechanical stress.

To maintain your PP tanks in India:

- Regularly inspect for cracks, leaks, or deformations.

- Ensure proper cleaning after each use to prevent residue build-up.

- Avoid exceeding the chemical or temperature limits specified by the manufacturer.

- Use protective linings if working with highly concentrated acids.

- Use proper personal protective equipment (PPE), such as gloves and goggles.

- Ensure adequate ventilation to manage fumes.

- Avoid overloading the tank beyond its rated capacity.

- Follow the manufacturer’s guidelines for chemical handling and tank use.

As experienced pickling tank manufacturers, we guide our customers on safe usage.

The lifespan depends on usage, chemical exposure, and maintenance but typically ranges from 5 to 15 years or more.

Related Blogs

Let’s Connect

Contact Us

We are live 24/7 and reply within 48 hours.

Get in Touch

-

-

-

Address

Survey No.584/1+2 – C,Nr. Akshar Industrial Estate Mahemdabad Highway Road,Vatva Ahmedabad-382445, Gujarat, India.