Have you ever wondered how factories and industrial settings maintain clean, breathing air? The secret lies in Fume Extraction System. These extraction systems are intended to catch and remove pollutants, toxins, and harmful vapors from the air in workplaces where chemicals, dust, and hazardous gasses are present.

As you go about your day working with industrial equipment or chemicals, fume extractors filter the air around you softly and efficiently to provide a safe breathing zone.

After filtration, all hazardous and airborne particles are retained within it. Thus, it protects equipment, and facilities by lowering health risks, fire risks, and other hazards connected with airborne pollution.

Without these technologies, many workplaces’ air quality would quickly become intolerable and even dangerous. For companies where airborne contaminants are a byproduct of regular activities, fume extraction is required.

Importance of Fume Extraction for Industrial Workplaces

As an industrial workplace, you recognize the significance of keeping the air clean and breathable for your personnel. So, adding Acid Fume Extraction System is essential for any factory or workshop that generates airborne pollutants such as dust, smoke, or chemical vapors.

It was not only used to remove toxic/acidic vapors from pickling tanks, preventing them from spreading and causing contamination on the shop floor.

And with this effective scrubbing and guaranteed compliance with the acid fume neutralization system’s emission restrictions, only an individually built fume extraction system optimized for the specific application can be achieved.

These systems are crucial for industrial activities to be safe and compliant. They improve working conditions by lowering exposure to hazardous gases and particles, which can lead to health problems such as asthma, respiratory disorders, and even cancer over time.

An acid fume extraction plant offers numerous benefits, including:

- Ensure employee and worker safety by removing hazardous odors from the workplace.

- Protecting industrial equipment from potential corrosive fume damage.

- Keeping the work area clean, which contributes to a more efficient and enjoyable working environment.

- Employee productivity will increase because they will be working in a safer, cleaner environment.

- Compliance with emission laws, lowering the possibility of fines and penalties.

- Accidents are less likely as a result of improved air quality and lower fume exposure.

- Increasing visibility in the galvanizing shop, hence fostering safer working conditions.

- Creating a more comfortable work atmosphere by preventing unwanted odors.

- It operates without producing effluent, making it an environmentally favorable option.

- Monitoring pH levels to ensure the extraction plant’s safe and effective functioning.

How Do Fume Extraction Systems Work?

Fume Extraction System Work in industrial settings by capturing and removing air pollutants. By filtering out harmful gases, dust, and other airborne contaminants, they help to improve air quality and worker safety.

Capture and Containment

The first step is to collect the contaminated air. This is where Zinc White Fume Extraction System comes into the picture.

As it consists of a fume extraction hood installed over areas where pollutants are discharged, such as welding stations or painting booths. Powerful fans draw filthy air into the hoods. The contaminated air is then sent through ducts to an air filter unit.

Air Filtration

The contaminated air is filtered through a series of filters to eliminate dangerous particles and gases. The sorts of filters utilized are determined by the contaminants in the air. Typical filters include:

- Particulate filters: These filters remove solid particles such as dust, smoke, and metal shavings.

- Activated carbon is a substance that absorbs volatile organic compounds (VOCs), fumes, and odors.

- HEPA filters: These filters are extremely effective in trapping airborne pollutants such as asbestos, lead, and mold.

- Acid gas filters: These filters neutralize and remove corrosive gases such as sulfur dioxide and hydrogen chloride.

The clean air is either vented outside or recirculated back into the workplace.

Monitoring and Maintenance

To work safely and efficiently, fume extraction systems require ongoing maintenance. Sensors monitor the system and alarm when pressure or air flow lowers. Filters must be inspected and replaced regularly, as recommended by the manufacturer.

Ductwork and fans should also be inspected regularly for damage or pollution build-up.

Proper fume extraction is critical for protecting occupational health and meeting workplace safety laws. When properly constructed and maintained, these systems can efficiently control harmful air pollutants while also providing employees with a safe working environment.

Fume extraction systems enable industrial operations that emit airborne pollutants to continue running sustainably by capturing and filtering contaminated air.

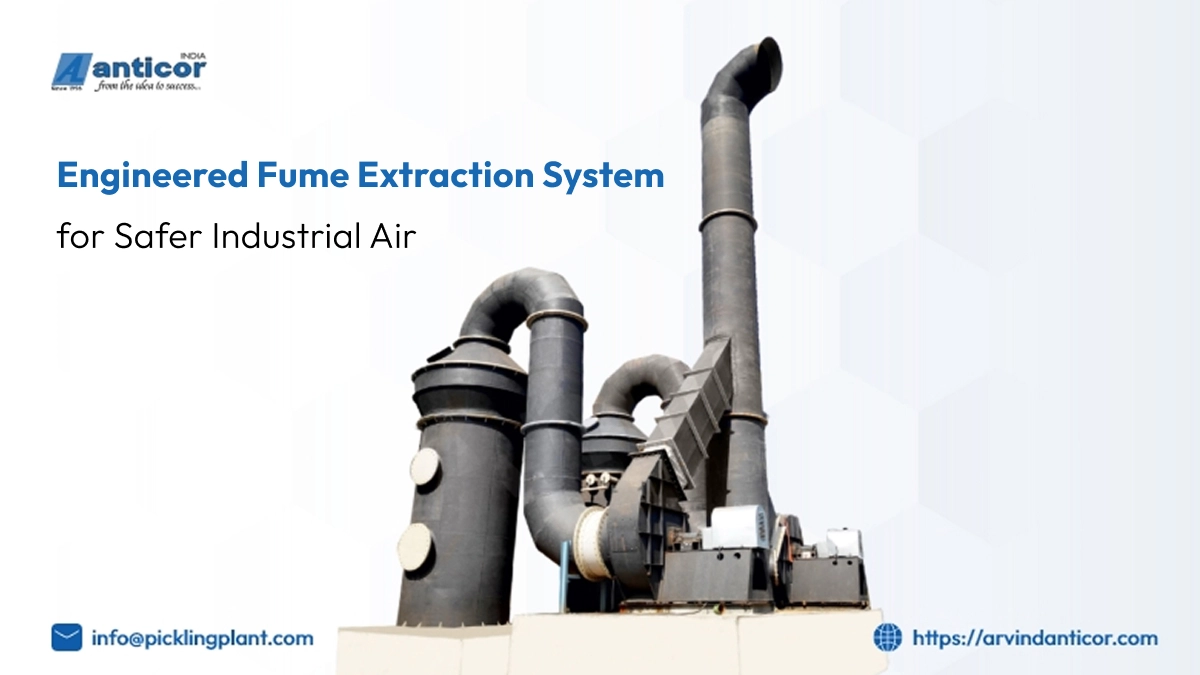

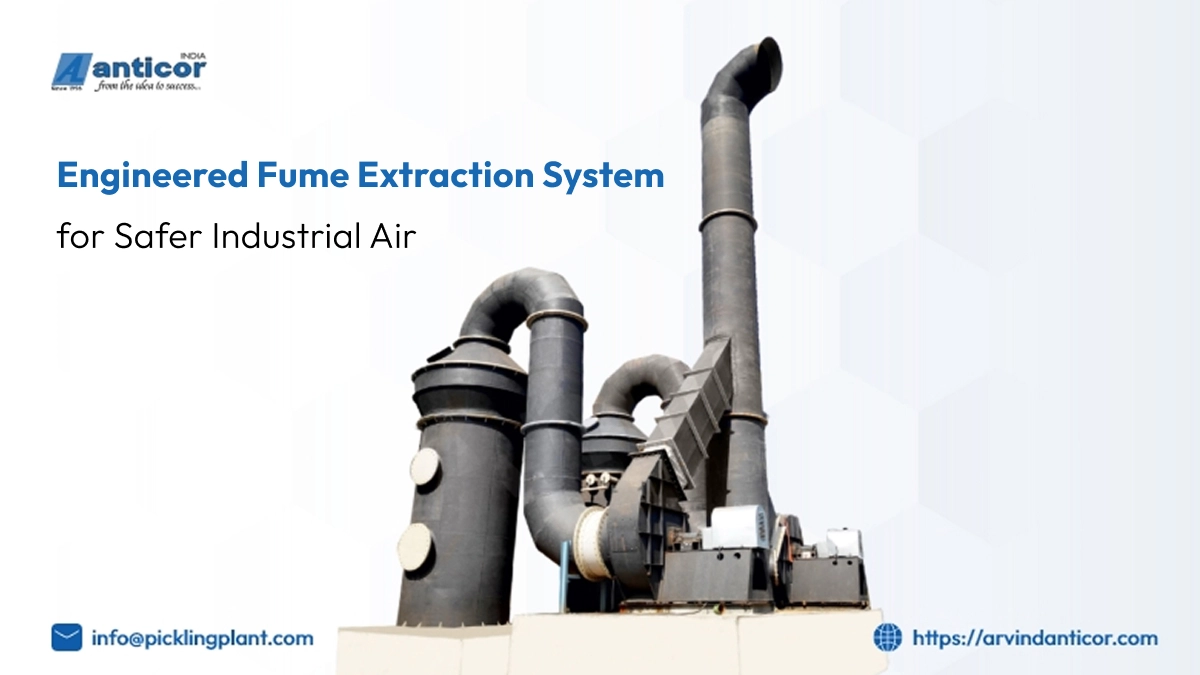

Key Components of an Industrial Fume Extraction System

A well-designed fume extraction system relies on several engineered components that work together to maintain consistent airflow and capture efficiency. Each component must be selected based on the type of fumes, operating conditions, and emission of load.

Key components include:

- Extraction hood positioned at the emission source to capture fumes before they spread.

- Corrosion-resistant ducting is made from PP, PPH, or FRP to safely convey acidic or chemical-laden air.

- Multi-stage filtration units such as particulate filters, activated carbon, HEPA, or packed-bed scrubbers.

- Induced draft fans engineered to maintain uniform suction and stable negative pressure.

- Airflow and duct design calculations are like the engineering used for polypropylene pickling tanks to minimise pressure loss.

Together, these elements ensure safe fume capture, smooth air transport, and long-term system reliability.

Engineering Considerations for a Reliable Extraction System

Engineering accuracy is essential for designing a dependable extraction system. Factors such as pollutant type, air temperature, capture velocity, and duct length all influence system performance and efficiency.

Important engineering considerations include:

- Correct capture of velocity to prevent fumes from dispersing into the workspace.

- Smooth duct routing reduces turbulence and pressure drops.

- Material selection, such as PP or FRP, to resist chemical corrosion.

- Application-specific filtration media for particulate matter, VOCs or corrosive gases.

- Integration with upstream processes such as the 7 Tank Phosphating Process for improved air quality.

- System monitoring with airflow, static pressure, and pH checks to maintain compliance with emission norms.

These engineering principles are the same foundations used in acid fume extraction systems, ensuring safe, efficient and compliant operation.

Choosing the Right Fume Extraction System for Your Industry

Choosing the right fume extraction system for your industry is crucial to ensuring a safe work environment and compliance with regulations. The specific type of system you need depends on several factors, including:

Type of Pollutants

The pollutants and chemicals used in your facility will determine what kind of filtration and extraction is required. For example, systems handling volatile organic compounds (VOCs) require high-efficiency filters and ducting, while dust and particulate matter may only need a basic filter. Some systems can handle multiple pollutants. Identify all the contaminants in your facility to choose a system that can properly extract and filter them.

Area of Coverage

Do you need to extract fumes from a single workstation, a production line, or an entire facility? Local exhaust ventilation systems handle a specific area, while broader general ventilation systems can cover an entire plant. Consider both the horizontal square footage as well as the vertical height that requires ventilation.

Airflow and Extraction Rate

The amount of air that needs to be extracted is measured in cubic feet per minute (CFM). A higher CFM means more air is filtered and replaced. For highly toxic pollutants, a faster extraction rate is critical. Work with an expert to determine the minimum CFM for your facility based on the pollutants present and the size of the area.

Ducting and Filters

The ducting, pipes, and filters transport and clean the polluted air. Choose a system with ducting and filters specifically designed for your types of pollutants. For example, grease and particulate matter require a HEPA filter, while chemical fumes need an activated carbon filter. The ducting should also be corrosion-resistant if handling acidic or alkaline chemicals.

Cost and Maintenance

Consider both the upfront capital cost as well as ongoing maintenance expenses. While a basic dust collection system may be inexpensive, a large-scale chemical fume extraction system requires a major investment.

Ongoing costs include filter replacement, duct cleaning, and other servicing needs. Choose a high-quality system that fits your budget and ensure you understand the long-term maintenance requirements.

Following these steps will help you determine the type of fume extraction system that is right for your facility’s needs and ensure many years of safe operation. Consult an expert for additional guidance on choosing and installing the proper ventilation equipment for your industry.

For the most comprehensive maintenance, schedule routine servicing by professionals trained to inspect and repair fume extraction systems. They can fully evaluate all components, test emergency systems, clean exhaust fans, and ductwork, replace air filters and make any necessary repairs to ensure your system is running safely and efficiently.

Professional servicing, while an added cost, provides the highest level of preventative maintenance to maximize the lifespan of your fume extraction system.

Operational Advantages and Long-Term Performance

A well-engineered fume extraction system delivers operational benefits beyond immediate air purification. By reducing corrosive fumes and maintaining clean air movement, the system protects equipment, minimizes downtime, and enhances workplace safety.

Key advantages include:

- Longer equipment life due to reduced corrosion and cleaner working environments.

- Improved visibility and comfort for operators in fume-heavy areas.

- Lower maintenance costs through controlled emission levels and stable airflow.

- Better compliance with safety and pollution control standards.

- Safer chemical handling when paired with secure storage such as chemical storage tanks.

With proper maintenance and engineered airflow, these systems become dependable for long-term assets for industrial operations.

Conclusion

Fume extraction systems play a critical role in maintaining safe and compliant industrial environments by capturing and filtering harmful fumes directly at their source. By using corrosion-resistant materials, proper airflow design and application-specific filtration, these systems protect equipment, improve air quality, and support consistent production performance.

For industries involved in chemical processing, metal finishing and high-emission operations, a well-designed extraction system ensures cleaner air, reduced maintenance requirements, and long-term operational efficiency. With the right engineering and routine servicing, Arvind Anticor delivers dependable fume extraction solutions that become essential assets for safer, more productive and environmentally responsible industrial workplaces.

Let’s Connect

Contact Us

We are live 24/7 and reply within 48 hours.

Get in Touch

-

-

-

Address

Survey No.584/1+2 – C,Nr. Akshar Industrial Estate Mahemdabad Highway Road,Vatva Ahmedabad-382445, Gujarat, India.