Due to their barrier properties, polymer plastics are ideal for a variety of packaging applications, as they help keep products fresh, prevent contamination, and extend shelf life. For the storage and transport of liquids and compounds, polyethylene (PE) and polypropylene (PP) containers are frequently used in a variety of industries. The unique properties of these materials make them appropriate for various applications. Similar to polyethylene, polypropylene, also known as polypropene, is a form of plastic. When there is a question of polyethylene vs polypropylene tank, the fact that polypropylene can be molded and becomes malleable above a specific temperature is what sets it apart from polyethylene.

In this blog, we will examine the polyethylene vs polypropylene tank comparison, and common applications of polyethylene vs. polypropylene tanks. By understanding the benefits and drawbacks of each material, you can make an informed decision when choosing a tank for your application. If you need a tank for anything from storing water and chemicals to holding agricultural or industrial goods, this blog will help you make an informed decision on the appropriate material for your specific use.

Difference between Polypropylene vs. Polyethylene Tanks

1. Chemical Structure:

Polyethylene and polypropylene are both polymers, meaning that they are large molecules composed of monomers that repeat. The polymer polyethylene is derived from the monomer ethylene (C2H4). When polymerized, ethylene derived from natural gas or petroleum forms long chains of polyethylene. Polyethylene’s repeating unit is -CH2-CH2-, which indicates that each monomer unit contains two carbon atoms and four hydrogen atoms. Polypropylene, on the other hand, is a polymer that is produced from the monomer propylene (C3H6), which is likewise obtained from natural gas or petroleum. Polypropylene is a thermoplastic polymer. When propylene is polymerized, it produces polypropylene chains with repetitive units of -CH(CH3)-. This indicates that each monomer unit in the polymer consists of three carbon atoms, six hydrogen atoms, and a methyl group (CH3) attached to one of the carbon atoms.

In polyethylene vs polypropylene tank comparison, it is important to note that polyethylene has a shorter chain length and no branching, whereas polypropylene has a longer chain length and does have branching in its chemical structure.

2. Strength and Durability:

In the debate of polypropylene vs polyethylene, due to its extended chain length and branching, polypropylene confers greater strength and impact resistance. Polypropylene tanks are renowned for their resilience, tensile strength, and resistance to tension fractures and impact damage. In addition, they are resistant to numerous compounds and can withstand higher temperatures than polyethylene containers. These properties make polypropylene containers ideal for conveying and storing aggressive chemicals and substances, including acids, bases, and solvents.

However, polyethylene tanks are weaker than polypropylene tanks and are susceptible to cracking under high stress or impact conditions.

The selection of polyethylene vs. polypropylene containers will depend on the particular application and specifications. If the tank must withstand high levels of stress or impact, or if it will be used to contain corrosive compounds, a polypropylene tank may be the best option.

3. Cost:

When comparing the costs of polyethylene vs. polypropylene for a particular application, it is essential to consider the product’s specific requirements and properties. In general, polyethylene is less expensive than polypropylene. This is due to the fact that polyethylene is simpler and less expensive to produce than polypropylene. In addition, polyethylene is more extensively used and accessible, so it is frequently less expensive to purchase. The cost of these primary materials can affect the cost of the completed product, with polyethylene being more economical than polypropylene due to the reduced cost of ethylene in comparison to propylene.However, the cost disparity may vary depending on the application and other variables, such as the material’s thickness and quality.

The manufacturing process for polyethylene is more straightforward and affordable than that of polypropylene when comparing polyethylene vs polypropylene tanks. Polyethylene can be produced through either a high-pressure or low-pressure polymerization process, which is both simple and useful.

4. Melting Point:

When comparing the melting points of polypropylene vs. polyethylene for a particular application, it is essential to consider the required product temperature. If resistance to extreme temperatures is required, polypropylene may be the best option.

Polypropylene has a higher melting point than polyethylene, ranging between 130°C and 171°C (266°F and 340°F) depending on the type of polypropylene. This is due to the structure of the polymer molecules, which are more densely packed than in polyethylene. In contrast to polypropylene, polyethylene has a lower melting point, ranging between 105°C and 137°C (221°F and 279°F). Polyethylene has a lower melting point than polypropylene due to its weaker polymer chain structure, which enables it to dissolve at lower temperatures.

5. UV Rays Resistance:

In the question of UV resistance in the debate of polypropylene vs polyethylene, the latter is more preferable. It is important to note that even though polyethylene containers are highly UV-resistant, they can still deteriorate over time if exposed to intense sunlight for an extended period of time. UV radiation can cause the polyethylene to become fragile, resulting in tank fractures and leakage.

Polyethylene containers are frequently used in outdoor applications due to their high resistance to ultraviolet radiation.

In addition, some polyethylene containers are manufactured with UV stabilizers that further improve their UV resistance. These stabilizers serve as a barrier between the polyethylene molecules and UV radiation, preventing the material from degrading and extending the tank’s lifespan.

Polyethylene vs. Polypropylene Tank Comparison: Common Application

Given the fact that polypropylene and polyethylene materials have different properties, their applications are different too. Due to their distinct properties and characteristics, polypropylene and polyethylene containers are both popular options for retaining and transporting liquids and compounds in a variety of industries. Both polypropylene and polyethylene containers have distinct benefits and drawbacks that make them suitable for a variety of applications. It is essential to consider chemical reliability, resistance to temperature, and robustness when choosing a tank for a particular application.

Let’s take a look at a list of applications where we choose polypropylene vs. polyethylene tanks:

Storage of chemicals:

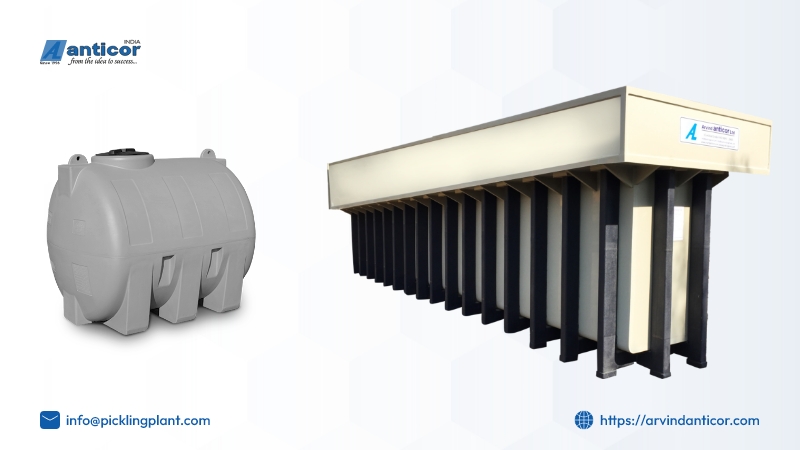

Due to its exceptional resistance to a diverse assortment of chemicals, acids, and alkalis, polypropylene tanks are an ideal material option for use in storage applications involving chemicals. The storage of chemicals such as hydrochloric acid, sulfuric acid, and sodium hydroxide are typical applications for these containers.

Electroplating:

Polypropylene tanks are a typical choice for use in electroplating applications for the purpose of storing and conveying the many different chemicals that are required for the process. They are not affected by the acids, alkalis, or any of the other chemicals that are used in the electroplating process.

Production of pharmaceuticals:

Polypropylene tanks are used in the mixing, storing, and transportation of a wide variety of chemicals and solutions during the production processes of pharmaceuticals. As a result of their resistance to the majority of pharmaceutical compounds as well as their ability to tolerate high temperatures, they are suited for use in the procedures that sterilize medical devices.

Water treatment:

Polypropylene tanks are a typical choice for use in water treatment facilities, both for holding water and for processing it once it has been filtered. They are not affected by chlorine or any of the other chemicals that are employed in the process of water purification.

Production of semiconductors:

They use polypropylene tanks for the purpose of storing and transferring the many chemicals that are required for the production process. They have an exceptionally high resistance to chemicals such as sulfuric acid and hydrochloric acid, both of which are often used in the production of semiconductors.

Not only this, there are other scenarios where using polyethylene vs polypropylene tanks play a key role.

Storage in agriculture:

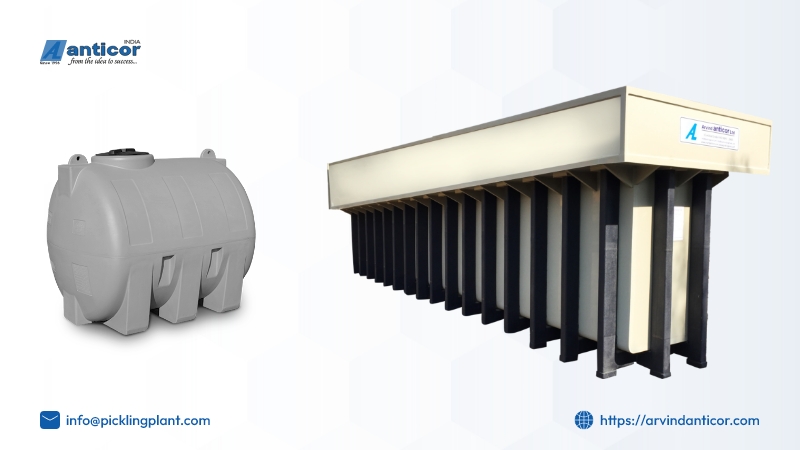

Polyethylene tanks are often used in the agricultural industry for the purpose of storing water, fertilizers, and many other chemicals. As a result of their resistance to ultraviolet radiation and their ability to endure severe weather conditions, they are suited for use outside.

Manufacturing of food and beverages:

The food and beverage sector makes extensive use of polyethylene tanks for the purpose of storing and transporting a wide variety of goods and materials. They are non-toxic and resistant to the majority of the chemicals used in the food industry.

Aquaculture:

Tanks made of polyethylene are often used in aquaculture for the purpose of holding fish and other aquatic creatures as well as transporting them. As a result of their resistance to ultraviolet radiation and their ability to endure severe weather conditions, they are suited for use outside.

Petrochemical industry:

In the petrochemical sector, polyethylene tanks are used for the purposes of storing a wide variety of chemicals and petroleum products as well as for their transportation. They are unaffected by the vast majority of chemicals derived from petroleum and are able to tolerate severe climatic conditions.

To sum it up…

In conclusion, while choosing the appropriate tank for a particular application, it is essential to have a solid awareness of the difference between polypropylene tanks vs polyethylene tanks. Tanks made of polypropylene are favored because of their higher resistance to chemicals and high-temperature tolerance. As a result, these tanks are perfect for storing and transporting hazardous materials and chemicals that are known to be particularly aggressive. On the other hand, polyethylene tanks are well-known for their affordability, durability, and resistance. These characteristics make them excellent for usage in agricultural and outdoor settings.

Whether you decide to go with a polypropylene vs polyethylene tank, it is essential to find a reliable polypropylene pickling tanks manufacturer that can provide you with high-quality tanks that are tailored to your particular preferences, prerequisites, and specifications.

Let’s Connect

Contact Us

We are live 24/7 and reply within 48 hours.

Get in Touch

-

-

-

Address

Survey No.584/1+2 – C,Nr. Akshar Industrial Estate Mahemdabad Highway Road,Vatva Ahmedabad-382445, Gujarat, India.