Wet scrubbers represent one of the most efficient technologies for controlling air pollution. These systems are essential for eliminating pollutants from exhaust emissions, promoting cleaner air and adherence to environmental regulations. This guide will examine the function of wet scrubbers, their operational mechanism, their effectiveness, and their benefits in industrial settings.

What Are Wet Scrubbers?

A wet scrubber is an air pollution control mechanism intended to eliminate harmful gases, dust, and particulates from industrial exhaust emissions by utilizing a liquid—usually water or a chemical solution. This device is commonly employed in sectors such as hot-dip galvanizing, metal processing, chemical production, and power generation to manage emissions and enhance air quality.

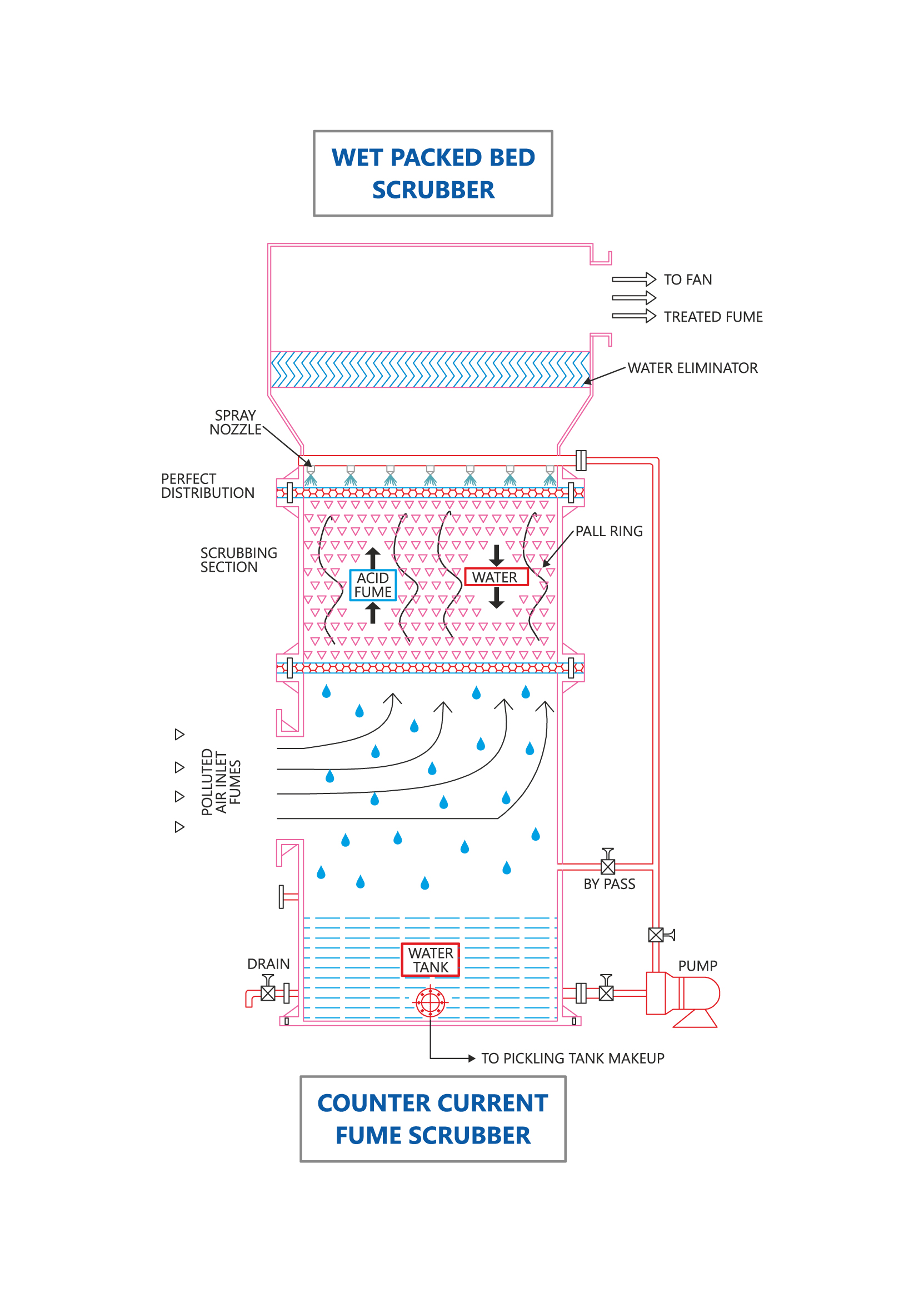

How Do Wet Scrubbers Work?

Step-by-Step Process of a Wet Scrubber:

- Polluted Air Enters the Scrubber :A fume extraction hood and duct system transport industrial exhaust fumes containing dust, metal oxides, and acidic gasses to the wet scrubber. The speed and direction of airflow are adjusted to maximize pollution capture.

- Scrubbing Action: Gas-Liquid Contact : Water (to eliminate general dust and particles). Alkaline solutions (for neutralizing acidic gases such as SO₂ and HCl). Chemical agents (to capture harmful gases like ammonia (NH₃) or chlorine (Cl₂)). The contact occurs through spray nozzles, packed beds, or venturi tubes, depending on the scrubber type.

- Pollutant Capture and Removal: The air goes through the liquid, and the pollutants dissolve, react and get trapped in the water droplets. Fine particles and gases are effectively absorbed or chemically neutralized. Heavy ash or large particles may settle at the bottom of the system.

- Pollutant Capture and Removal: The air goes through the liquid, and the pollutants dissolve, react and get trapped in the water droplets. Fine particles and gases are effectively absorbed or chemically neutralized. Heavy ash or large particles may settle at the bottom of the system.

- Separation of Clean Air & Polluted Liquid: The air purified is expelled through an exhaust stack. To avoid moisture carryover, a mist eliminator is employed to eliminate any water droplets prior to discharge.

- Waste Liquid Handling & Disposal: The polluted scrubbing liquid is either processed through a treatment system for reuse or properly disposed of in accordance with environmental regulations.

How Wet Scrubbers Are Used in Different Industries

Wet scrubbers are crucial systems for controlling air pollution, utilized in a range of industries to eliminate harmful gases, particulate matter, and toxic vapors from emissions. Their usage differs based on the specific pollutants produced in each sector. Here’s an overview of how wet scrubbers are implemented across various industries:

| Industry | Primary Pollutants | Application of Wet Scrubbers |

| Hot-Dip Galvanizing Industry | Zinc fumes, hydrochloric acid (HCl), sulfuric acid (H₂SO₄) vapors | Captures acidic vapors released during the pickling and galvanizing process. Prevents corrosion damage to nearby equipment and infrastructure. Ensures compliance with air quality regulations by reducing hazardous emissions. |

| Metal Processing & Foundries | Metal oxides, fine dust, toxic fumes (lead, cadmium, zinc) | Removes particulate matter and metal oxides produced during melting and casting. Prevents the release of toxic metal fumes, protecting workers and the environment. Venturi scrubbers are commonly used due to their high efficiency in dust collection. |

| Chemical & Pharmaceutical Industries | Toxic gases (chlorine, ammonia, hydrogen sulfide, VOCs) | Neutralizes hazardous gaseous emissions before they are released into the atmosphere. Controls volatile organic compounds (VOCs) that contribute to air pollution. Packed bed scrubbers are ideal for absorbing acidic or alkaline gases. |

| Power Plants & Energy Sector | Sulfur dioxide (SO₂), nitrogen oxides (NOx), fly ash | Used in Flue Gas Desulfurization (FGD) to remove SO₂ and NOx from coal-fired power plants. Reduces acid rain-causing emissions by neutralizing acidic gases with limestone slurry. Spray tower scrubbers and venturi scrubbers are widely used for handling large gas volumes. |

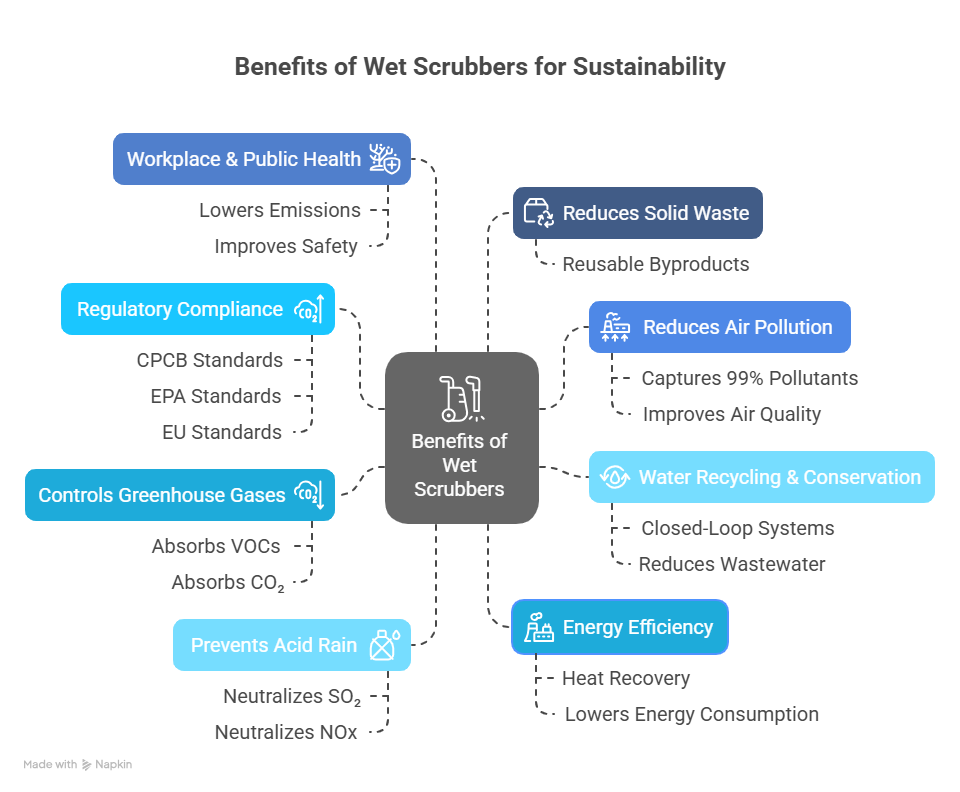

Why Wet Scrubbers Are Important for sustainability

Conclusion

Wet scrubbers play a vital role in industrial air pollution control, ensuring cleaner emissions and safer workplaces. By understanding their working principles, industries can optimize their fume extraction systems for maximum efficiency and compliance. If your business requires a reliable wet scrubbing system, consider investing in high-quality, corrosion-resistant solutions tailored to your needs.

At Arvind Anticor Limited, we specialize in high-performance wet scrubbers designed with corrosion-resistant thermoplastics to ensure durability and efficiency in harsh industrial environments. Our advanced zinc fume extraction system and acid fume extraction systems help businesses meet environmental regulations while reducing operational costs.

Need an advanced wet scrubber for your facility? Contact us today to explore the best solutions for your industry!

Let’s Connect

Contact Us

We are live 24/7 and reply within 48 hours.

Get in Touch

-

-

-

Address

Survey No.584/1+2 – C,Nr. Akshar Industrial Estate Mahemdabad Highway Road,Vatva Ahmedabad-382445, Gujarat, India.