Strategic Partnerships

Integrating World-Class Products, Software, and Technology for Superior Solutions

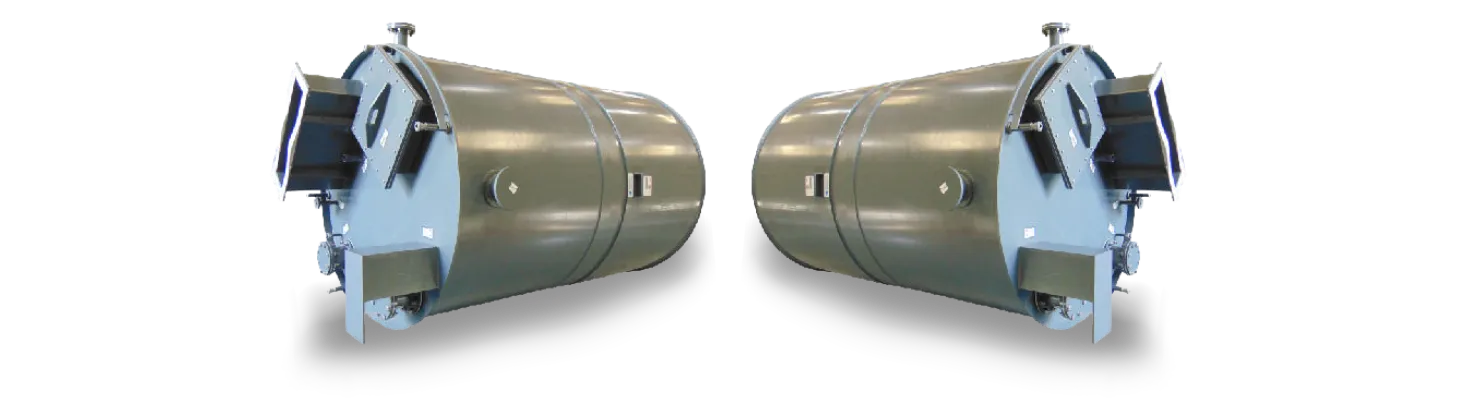

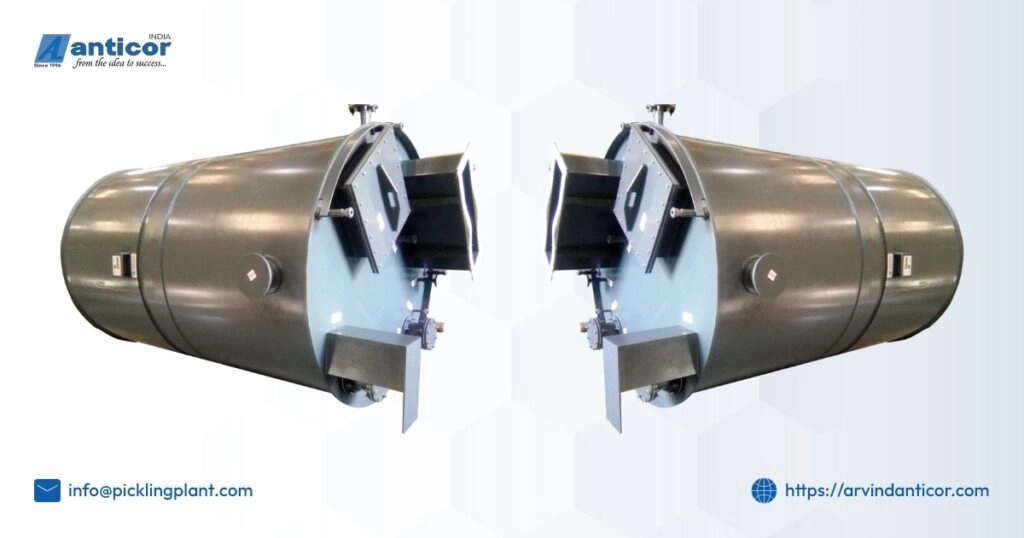

FRP Chemical Storage Tanks

Arvind Anticor is a pioneer amongst the FRP tank manufacturers in India. Our extensive range of FRP storage tanks comprises of horizontal and vertical tanks that can be used for chemical storage, water storage, liquid storage and many other applications.

Some interesting qualities of our FRP chemical storage tanks are light in weight, easy to handle, corrosion resistance and resistant to any attack from bacteria that may normally be expected in cold water applications.

The features of FRP tanks to withstand corrosive chemicals and high temperature has enabled us to become one of the most popular FRP tank suppliers. The high quality pp FRP tanks are equipped with level indicator and all standard accessories.

Specifications

- Planning & construction of tank system with fume exhaust system.

- Robust design of tank made out of Industrial Thermoplastic.

- Environment friendly Fume Extraction System, avoiding corrosion of surrounding steel construction, cranes and roof structure.

- Plastic Tanks available in flat pack modules (reduced volume)

- Heating and circulation system available. (optional)

- Tank made from Industrial Thermoplastic and welded with state-of-the-art hot gas extrusion welding process and stress relieved.

- Modules assembled and welded at site for easy transportation.

- 100% leak proof welding.

- Fume free work place.

- Corrosion free atmosphere.

- Tanks are available up to 40 meter length.

Why Choose Our Tanks?

Exploring Applications, Benefits, Features and Industry Uses

- Portable water storage tanks

- Chemical storage tanks

- Blending tank

- Water and waste treatment tanks

- Mobile tanks mounted on trailers

- High pressure lightweight cylinders

- Manufactured in compliance with German DVS standards

- Leakage proof

- Safe handling

- Required accessories are provided

- Custom design as per client requirements

- Equipped with manhole, airvent, inlet connection

- Corrosion resistant

- Maintenance free

- Long service life without replacement or maintenance

- Safe for the environment

- Light weight

- Easy installation

- Smooth inner surface which means lower sludge formation and lower cleaning costs

- Chemical Industry

- Water and wastewater treatment

- Agriculture

- Pharmaceuticals

- Power and Energy

- Automotive Industry

Gallery of FRP Storage Tanks

View the Strength and Durability of Our High-Performance FRP Tanks.

Any Questions ? We Got You.

FRP tanks can store a wide range of chemicals, including:

- Acids (e.g., hydrochloric acid, sulfuric acid, nitric acid)

- Alkalis (e.g., sodium hydroxide, potassium hydroxide)

- Solvents and hydrocarbons

- Wastewater and effluents

- Fertilizers and pesticides

The specific resin used in the tank construction determines its compatibility with the chemical.

FRP tanks are manufactured using processes like:

- Filament winding: Fiberglass is wound around a mold in specific patterns to ensure strength.

- Hand lay-up: Layers of fiberglass and resin are manually applied to a mold.

- Spray-up: Fiberglass and resin are sprayed onto the mold.

FRP tanks are available in a wide range of sizes, from 500 liters to over 100,000 liters, depending on the application. Custom sizes can also be manufactured.

Yes, FRP tanks can handle moderate to high temperatures depending on the resin used. Typically, they can withstand temperatures up to 100-120°C. High-temperature resins can be used for even greater resistance.

Yes, FRP tanks are highly durable and weather-resistant. UV-resistant resins can be added for outdoor applications to protect against sun damage.

FRP tanks are highly durable and can last 15-20 years or more with proper maintenance. Their resistance to corrosion and environmental factors makes them ideal for harsh conditions.

Related Blogs

Let’s Connect

Contact Us

We are live 24/7 and reply within 48 hours.

Get in Touch

-

-

-

Address

Survey No.584/1+2 – C,Nr. Akshar Industrial Estate Mahemdabad Highway Road,Vatva Ahmedabad-382445, Gujarat, India.