Strategic Partnerships

Integrating World-Class Products, Software, and Technology for Superior Solutions

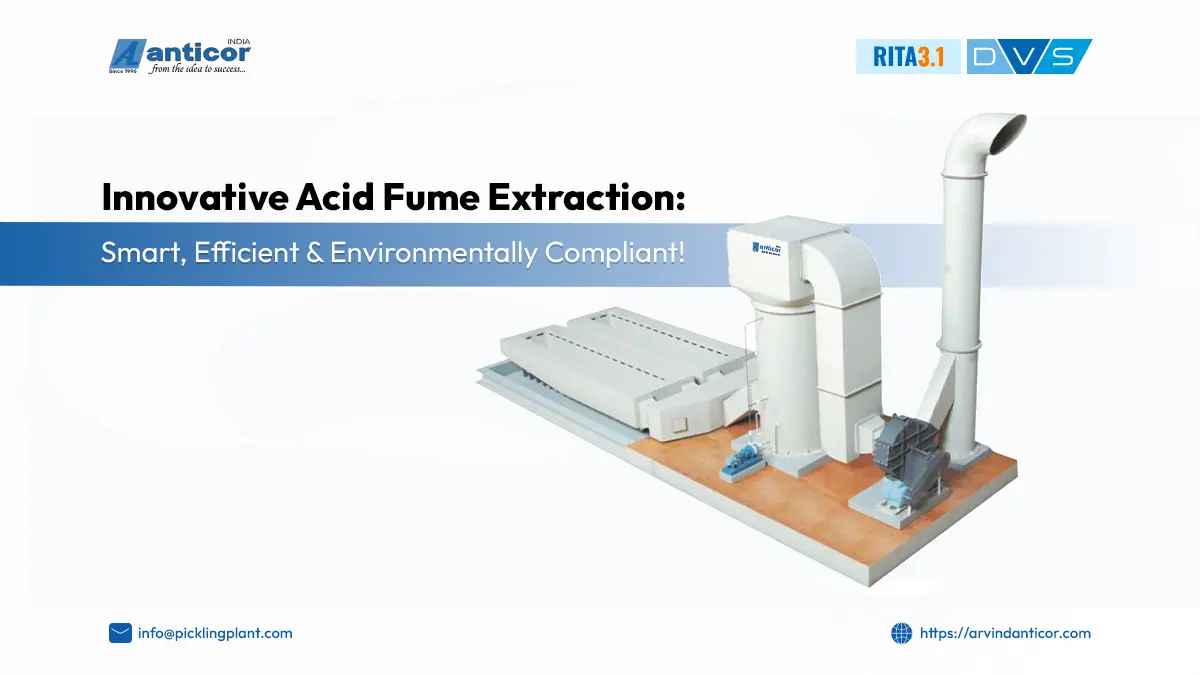

Acid Fume Extraction Systems

Acid fume extraction system is used to take the toxic/acidic fumes away from pickling tanks and prevent them from spreading on the shop floor and causing pollution. The acid fume scrubbing system prevents the release of aggressive and harmful vapors in the environment. Scrubbing liquid absorbs the vapors and gases and are returned to the process. Effective scrubbing and guaranteed compliance with emission limits of the acid fume neutralization system can only be achieved through an individually designed fume extraction system optimized on the particular application.

We have successfully become one of the leading fume extraction system manufacturers and suppliers in India as our products can be designed to meet specific high demanding emission regulations. We provide complete equipment supply and engineering services to give high quality fume extractors at a low price. We support our customers with installation, start-up assistance, training and field service of chemical fume extractors.

Each wet scrubber is manufactured and designed for individual customer requirements. We check the fume removal requirements to create the best design parameters for each installation. At Arvind Anticor, complete fume scrubbers’ systems are designed and built including multiple stages whenever required.

Our wet scrubbers are designed to remove toxic/acidic fumes from industrial exhaust air stream providing excellent air pollution control. Fume scrubbers are made to absorb toxic particles from air streams using water to scrub the air. A liquid solvent absorbs the fume pollutants by chemical or physical ways. A downwards blow from the tank with makeup water addition removes polluting substances before they precipitate.

Specifications

- Material: Made from high-quality, corrosion-resistant thermoplastics.

- Function: Prevents the release of harmful acid vapors by effective scrubbing.

- Process: Absorbs vapors and gases into the scrubbing liquid, returning them to the process.

- Design: Suitable for encapsulated pretreatment plants and lateral suction channels on pickling tanks.

- Performance: Ensures effective scrubbing with guaranteed compliance to emission limits.

- Calculation: Exhaust air volume and pressure loss determined by proprietary software.

- Regulatory Compliance: Supplies MACT (Maximum Achievable Control Technique) as per regulatory standards.

Why Choose Our Extraction Systems?

Exploring Features, Accessories, and Industry Uses

- Prevents harmful acid vapors from polluting the environment.

- Captures and recycles vapors, reducing waste and improving resource efficiency.

- Tailored designs ensure maximum performance for specific industrial needs.

- Complies with stringent emission regulations, enhancing workplace safety.

- Supports high-demand emission requirements with scalable performance.

- Reduces operational and maintenance costs with efficient scrubbing systems.

- Fume Extraction Hoods

- Ducting and Piping

- Scrubbers (Wet or Dry)

- Blowers/Fans

- Drainage Systems

- Stack/Chimney

- Pressure Gauges

- Chemical Industry

- Water and wastewater treatment

- Agriculture

- Pharmaceuticals

- Power and Energy

- Automotive Industry

Gallery of Acid Fume Extraction Systems

A Closer Look at Our Advanced Acid Fume Management Solutions

Any Questions ? We Got You.

The main types include:

- Wet scrubbers: Use water or chemical solutions to neutralize acid fumes.

- Dry scrubbers: Use activated carbon or chemical filters for fume absorption.

- Ductless fume hoods: Portable systems for localized extraction.

- Custom-designed systems: Tailored for specific industrial processes and environments.

The size and capacity depend on:

- Volume and concentration of acid fumes generated.

- Size of the workspace or process area.

- Required airflow rate (measured in CFM – cubic feet per minute).

- Type of acid used and its chemical properties.

With proper maintenance, these systems can last 10-20 years, depending on the materials used and the operational environment.

Yes, many systems are designed for seamless integration into existing facilities, with custom ductwork and adaptable components.

Yes, modern systems are designed to minimize environmental impact by:

- Neutralizing harmful fumes before release.

- Reducing chemical emissions.

- Ensuring compliance with environmental standards such as EPA or local regulatory bodies.

Related Blogs

Let’s Connect

Contact Us

We are live 24/7 and reply within 48 hours.

Get in Touch

-

-

-

Address

Survey No.584/1+2 – C,Nr. Akshar Industrial Estate Mahemdabad Highway Road,Vatva Ahmedabad-382445, Gujarat, India.