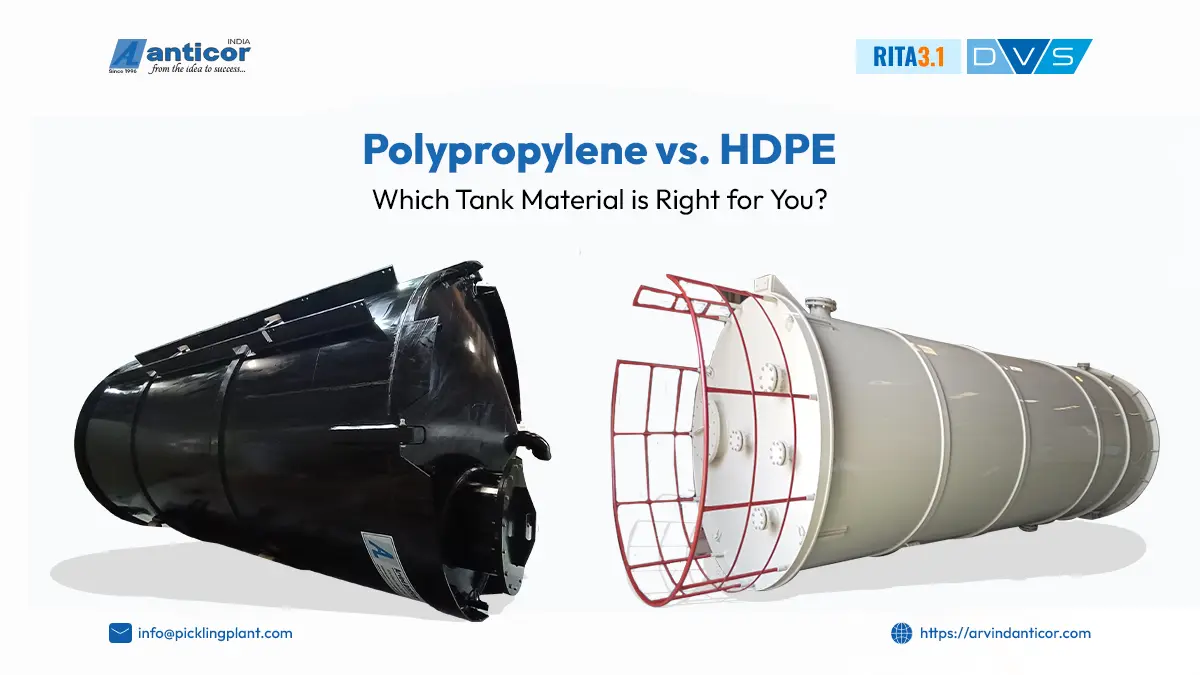

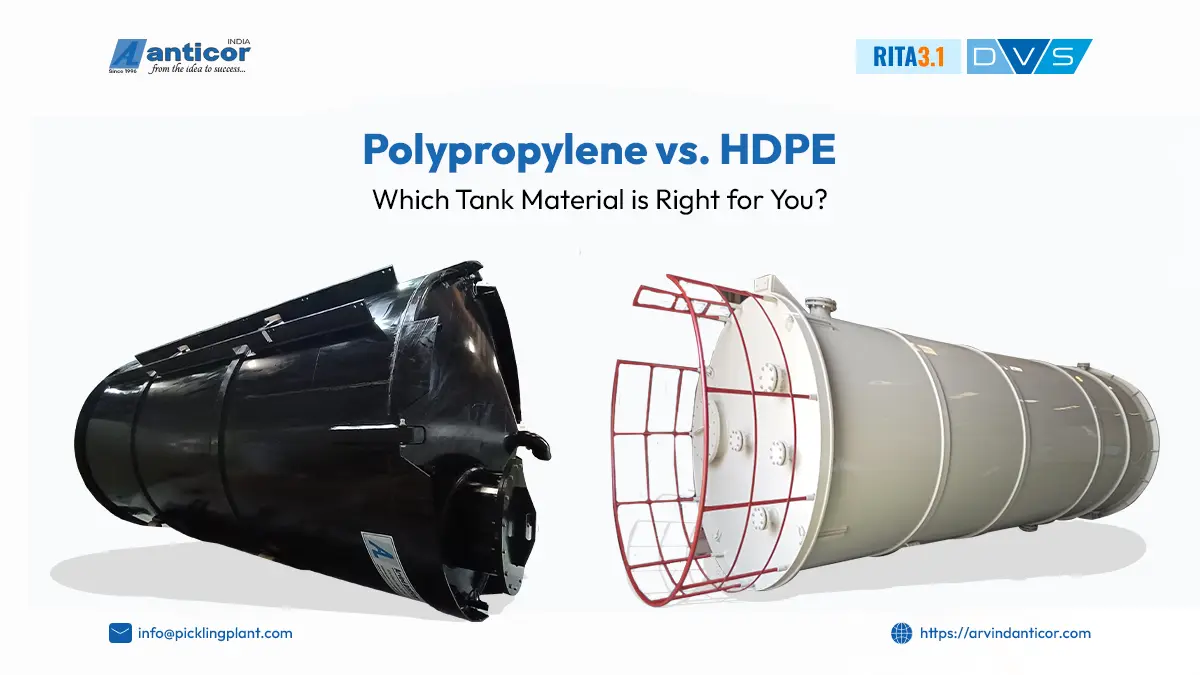

When you’re investing in storage tanks for industrial or commercial use, the material you choose can significantly impact safety, longevity, and performance. Two of the most popular plastic materials in the market are Polypropylene (PP) and High-Density Polyethylene (HDPE). While they may look similar at first glance, they serve different purposes and excel in different environments.

This blog offers a detailed comparison guide on polypropylene vs HDPE tank types—breaking down technical differences, use cases, pros and cons, and decision-making tips. For a broader perspective on plastic tank materials, you can also read our Polyethylene vs Polypropylene Tank guide. Breaking down technical differences, use cases, pros and cons, and decision-making tips. Understanding the differences between HDPE vs polypropylene tank alternatives is crucial for selecting the best fit, whether of your industry, water treatment, manufacturing, or agriculture.

Quick Comparison Table: Polypropylene vs HDPE Tank

| Feature | Polypropylene (PP) Tank | HDPE (High-Density Polyethylene) Tank |

| Temperature Resistance | Up to 100°C (212°F); high thermal tolerance | Up to 80°C (176°F); not ideal for sustained high heat |

| Chemical Resistance | Excellent against strong acids, alkalis, and solvents | Very good but less durable with aggressive solvents |

| Impact Resistance | Rigid, more brittle under physical shock | Highly flexible and durable under impact |

| UV Resistance | Moderate; requires UV additives for outdoor use | Excellent (especially UV-stabilized grades) |

| Weight | Lighter than HDPE; easier to handle | Slightly heavier but still portable |

| Cost | Higher due to better chemical and heat resistance | Cost-effective for most general-purpose use |

| Customization | Easier to weld, mold, and fabricate into custom shapes | More difficult to fabricate for complex designs |

| Common Applications | Chemical tanks, electroplating, lab use | Water tanks, agriculture, food processing, wastewater systems |

1. Temperature Resistance: Polypropylene vs HDPE Tank in Heat Applications

Polypropylene tanks are suitable for environments involving high-temperature liquids or heated processes. Even under heat stress, they maintain their structural stability with a tolerance of up to 100°C. Because of this, polypropylene tanks can bear hot liquids without warping or weakening, which is essential in sectors like metal treatment, chemical processing, and pharmaceuticals. Even slight deformation in these conditions can jeopardize product integrity.

In contrast, HDPE tanks can only manage up to 80°C, making them more appropriate for ambient-temperature liquids.

Best for: Heat-intensive chemical processes = Polypropylene

2. Chemical Compatibility: Polypropylene vs HDPE Tank for Corrosive Storage

When it comes to storing corrosive materials like acids, alkalis, or reactive solutions, Polypropylene is the material of choice. You can also refer to our HDPE Chemical Storage Tanks Selection Guide for application-specific recommendations across different chemical types.. It resists chemical degradation for long periods, even in aggressive environments.

HDPE handles most common chemicals like water, mild cleaning agents, and fertilizers but may break down faster with reactive solvents.

Best for: Chemical and lab storage = Polypropylene

3. Impact Resistance: Polypropylene vs HDPE Tank Under Physical Pressure

HDPE tanks are known for their toughness and shock-absorbing qualities. They can flex under pressure and bounce back without cracking, making them ideal for mobile or high-activity environments.

Polypropylene, being rigid, may crack or break under sudden impact or pressure.

Best for: Rugged field conditions and transport = HDPE

4. UV & Outdoor Resistance: Polypropylene vs HDPE Tank in External Environments

HDPE particularly UV-stabilized grades is built to withstand outdoor conditions, including direct sunlight, rain, and humidity.

Polypropylene requires additional UV stabilizers or coatings if used outside, which can increase costs and maintenance.

Best for: Farms, rooftops, and exposed installations = HDPE

5. Cost: Budgeting for Polypropylene vs HDPE Tank Investment

From a cost perspective, HDPE tanks are more affordable. They offer reliable performance for general storage at a lower price point.

Polypropylene tanks, although more expensive, provide value in high-performance environments where chemical resistance or heat tolerance is critical.

Best for: Budget-conscious general use = HDPE

6. Customization & Fabrication: Polypropylene vs HDPE Tank Design Flexibility

Polypropylene is easier to mold, weld, and shape into custom configurations. If your project needs special fittings, multiple chambers, or advanced plumbing integration, PP is more flexible.

HDPE is more rigid in fabrication, and while possible, customizations are more limited.

Best for: Complex engineering and custom layouts = Polypropylene

7. Portability: Mobility and Handling of Polypropylene vs HDPE Tank

Both materials are significantly lighter than metal tanks, but Polypropylene is even lighter than HDPE. This makes it preferable for portable tanks, rooftop installations, or temporary use cases.

Best for: Lightweight and mobile setups = Polypropylene

8. Industry Applications for Polypropylene vs HDPE Tank

Polypropylene Tanks

Explore our high-performance Polypropylene Pickling Tanks engineered for durability in chemical and high-temperature environments.

- Chemical manufacturing and handling

- Electroplating units

- Pharmaceutical storage

- Laboratory storage

- Heat-involved processes

HDPE Tanks

Looking for a reliable, affordable solution? Check out our HDPE Chemical Storage Tanks ideal for agriculture, water, and general-purpose chemical storage.

- Agriculture and irrigation

- Food and beverage processing

- Rainwater harvesting

- Wastewater treatment

- Household or commercial water storage

Match your tank material to the industry needs.

Final Verdict: Choosing the Right Polypropylene vs HDPE Tank

The choice between polypropylene vs HDPE tank depends on the chemical profile, temperature, usage conditions, budget, and location of installation.

- Choose Polypropylene if you deal with harsh chemicals, heat, or need a custom-built solution.

- Choose HDPE if you want a durable, affordable tank for everyday storage or outdoor use.

Still undecided? A deeper look at your operating environment, chemical exposure, and structural needs will help you determine which polypropylene vs HDPE tank solution is right.

Need help choosing the right storage tank for your application?

Reach out to our team today and get a personalized recommendation.

Let’s Connect

Contact Us

We are live 24/7 and reply within 48 hours.

Get in Touch

-

-

-

Address

Survey No.584/1+2 – C,Nr. Akshar Industrial Estate Mahemdabad Highway Road,Vatva Ahmedabad-382445, Gujarat, India.